Cut Throat Diaries is a series featuring our customers and their experiences using a straight razor. We believe that the straight razor can be used by any person to cut any hair regardless of gender, sexuality, race, or ability. All it takes to shave with a straigh razor is a willingness to learn. We hope you will decide to learn the art of straight shaving and #ditchthedisposable just like today’s guest!

Back in September, Alex Young--a barber in Richmond, VA--made the pilgrimage to Portland to visit our workshop. After getting his razors tuned up and learning more about our manufacturing process, Alex was kind enough to share his experience using our razors in a high-volume barbershop.

What Happened When I Switched to a Real Straight Razor in a High Volume Barbershop

Q. Thanks for your visit in September! It was great to finally meet you in real life.

It was a pleasure meeting you and Sarah in person!!

Q. Tell us about yourself! What’s your background, how long have you been a barber, etc?

My name is Alex Young and I currently work at High Point Barbershop in Richmond, Virginia. I've been a licensed barber in the state of VA since October 2017. I did a little bit of everything before getting into the barber trade: military, college, bartending/bouncing... I moved to Los Angeles in 2014--I think--and I started barber school at Borners Barber College (IG @bornersbarbercollege) near Inglewood in July 2016.

About halfway through my day I strop the Peacemaker again, sanitize it, and go on with my day. If you're only using it on the back of the neck, you only need to strop it maybe two times a day

Q. When did you first become aware of Portland Razor Company?

I vaguely remember seeing an Instagram post from @barber_fabian. I kind of glanced over the Portland Razor Company website but left it alone for a little while. I eventually messaged Fabian and asked him a million and a half questions and started doing research on how to use conventional straight razors in Virginia.

Q. What ultimately made you decide to take the leap and shop with us?

Once I found out it was legal to use them in my state and had some Xmas money to blow, I placed my order for The Peacemaker. I used it for a week and liked it so much I bought two more razors in different blade lengths!

Q. What does a normal day in the barbershop look like for you?

A normal day for me is various combinations of hot towel shaves, beard trims (we do full beard trims with razor lineups and throat shaves), and haircuts. I work in a pretty high volume shop and see roughly 14-16 people a day on a normal day.

Q. How do you use our razors in the shop?

I use three different Portland razors in various lengths: a 1.75-inch Cascade Steel, The Peacemaker, and a 2.5-inch Cascade Steel. All have different uses for me. I strictly use the 2.5 for full face and head shaves, I use the 1.75 for beard trims with the throat shave and line up, and I use the Peacemaker for shaving the back of necks, hard parts and shape-ups for haircuts.

Q. What tools did you shave with before? What are the biggest differences you’ve noticed?

I used Irving Barber Company shavettes before. They're good shavettes by good people, but I decided I wanted to go to the more traditional side of things and use conventional straight razors. The biggest difference I've noticed is you get more feedback from the conventional razor than the shavettes. Like, I can feel in my fingertips every hair that's being cut. The sound is pretty satisfying as well!

Q. What changes have you noticed since switching to conventional straight razors?

I've noticed that I haven't had to worry about a "bad batch" of disposable DE blades, no burrs, no bullshit.

Q. What has the response been from customers?

“Don't be afraid to nick your strop, no one is perfect.”

It varies. The younger ones don't notice it too much, the older folks love it; they appreciate the kind of skill it takes to strop and maintain. In a generation of people who are bringing the barber shop back, the previous generations seem to be very happy that "real barbers are back." My tips got better, too!

Q. A lot of professionals are concerned about the time it takes to strop and hone a straight razor. Is there a place for conventional straight razors like ours in a high-volume shop setting?

Honestly, it takes some work, but not as much as one might think. Take me for example: when I get into work I strop all three of my razors and then put them all in a high level barbicide for 10 mins. I then take all three out, rinse them water, and wipe them off. Everything but the Peacemaker goes back into biodegradable travel toothbrush holders until I need them. After I use the Peacemaker--which is every haircut--it goes into high level. About halfway through my day I strop the Peacemaker again, sanitize it, and go on with my day. If you're only using it on the back of the neck, you only need to strop it maybe two times a day.

The other razors get stropped and sanitized immediately after they get used for shaves and beard trims, every single time.

Q. Do you have any tips or words of wisdom that might help a barber be successful with their new straight razor?

Don't be afraid to nick your strop, no one is perfect.

Slow is smooth, smooth is fast when it comes to stropping.

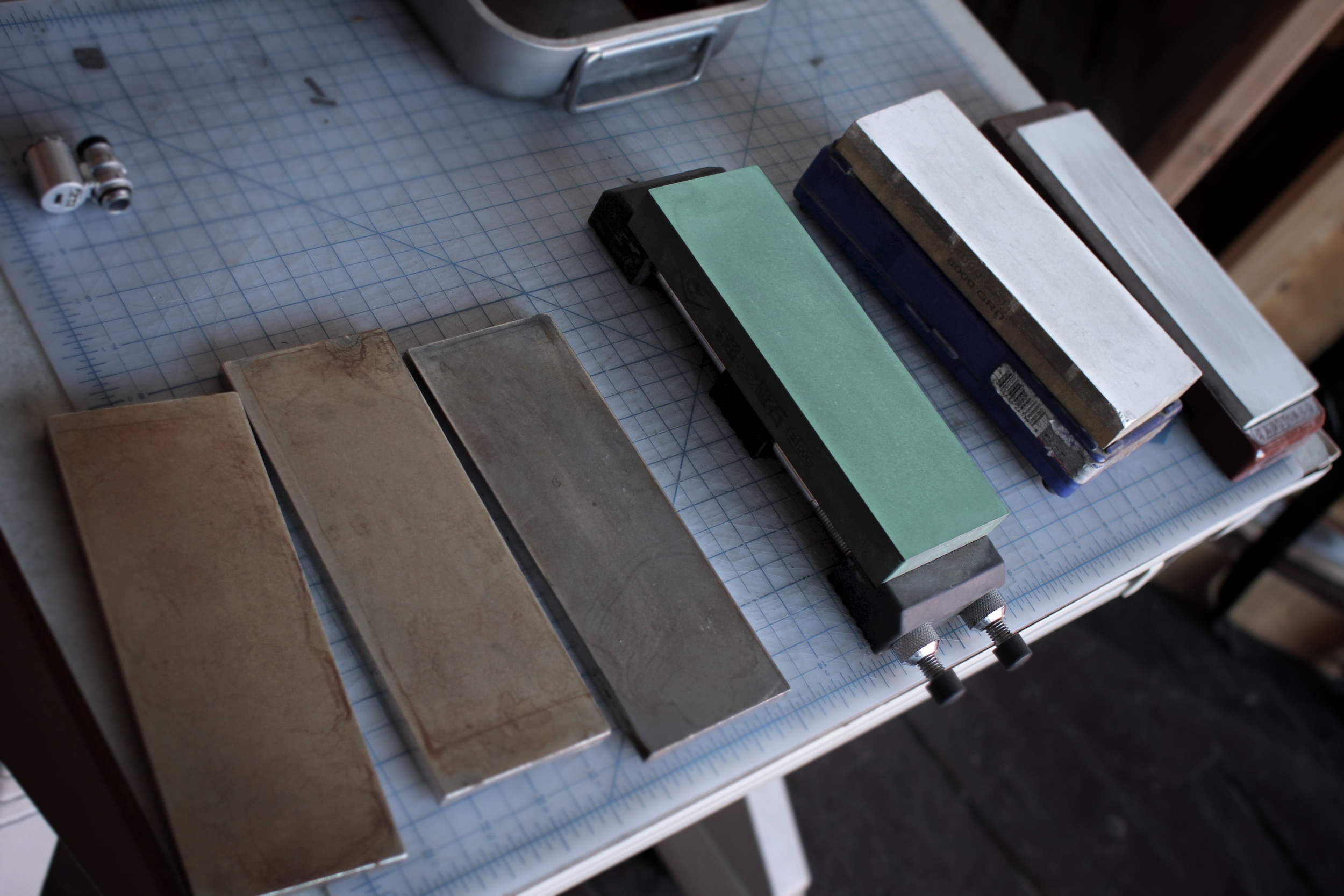

Don't be afraid to learn on your own about how to touch up your straight razor with your own hones. There are a lot of resources on the web, including Portland Razor Company and other sources on YouTube.

Q. Finally, where can our readers find you online/get in touch/schedule an appointment with you?

Work IG: @highpointbarbershop

My IG: @alex_gfy

If you're in the Richmond area and want to make an appointment, give the shop a call at 804-762-0260.