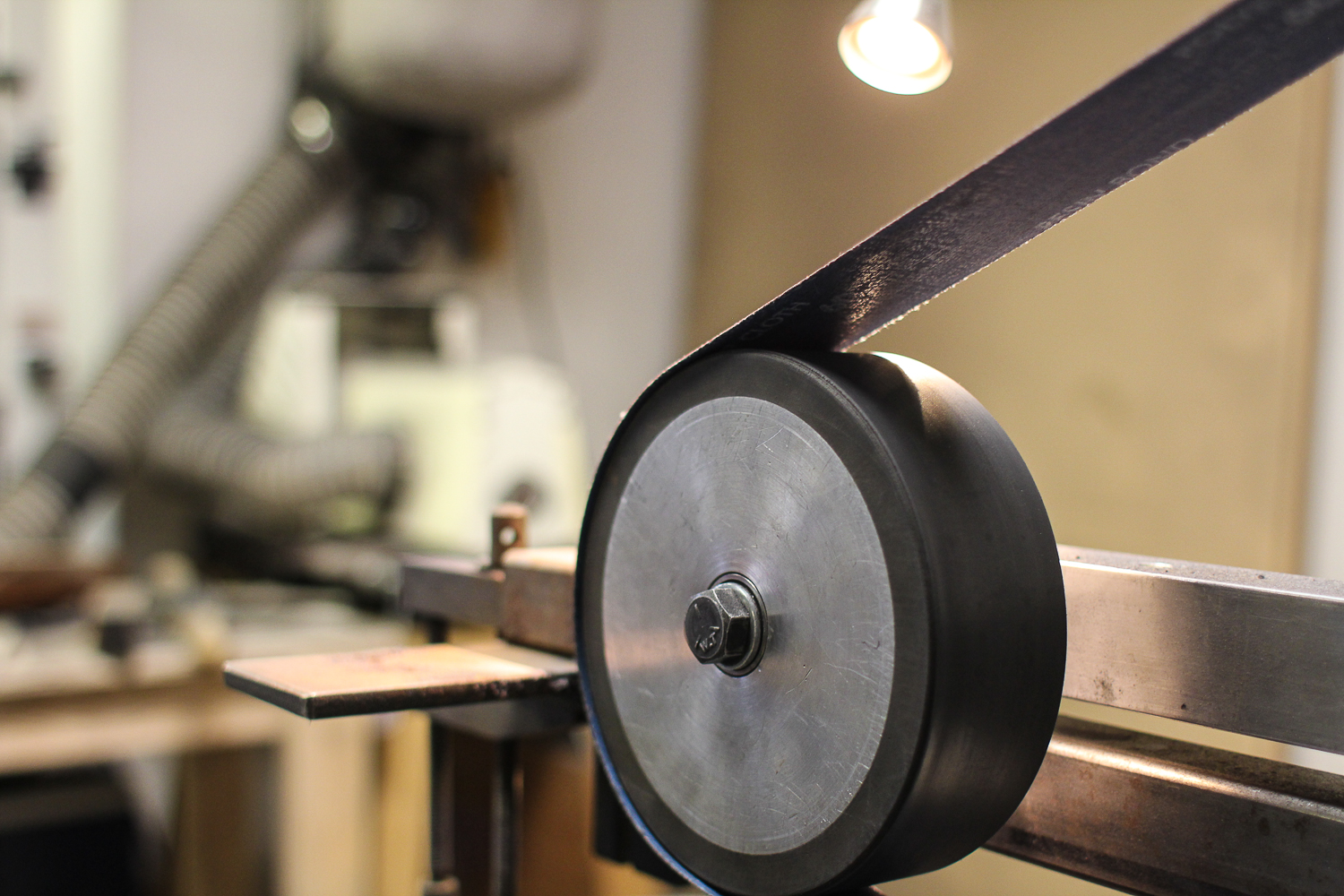

The day-to-day reality of tool maintenance is not glamorous, but we believe it is necessary and something to take pride in. At Portland Razor Co. we work hard to keep grinders lubricated, laser lenses clean, and saw blades sharp! By lapping our hones between sharpenings, we guarantee that each blade will be as sharp as the one before it. Our work would be impossible without these tools, and we honor them and the work they perform by committing time to caring for them.

Just as our tools are essential to crafting a quality razor, so are a barber’s in crafting a quality haircut, shave, or beard trim. Sharp tools work effortlessly, allowing you to focus on the important things: creating a work of art and building relationships with the person in the chair before you.

In an effort to better support our professional clients, we now offer scissor (aka beauty shear) and clipper sharpening services in addition to our very popular straight razor honing service. You can bring your tools to Portland Shave Shop to be sharpened while you wait, or you can mail them in to us, similar to our razor honing service. Barbershops and Salons in the Portland, OR area may also schedule mobile sharpening services to be performed by a Portland Razor Co. bladesmith at your shop!

Tools We Hone

Straight razors

Japanese-style convex edge scissors

German-style beveled scissors

Texturizing scissors

Clipper blades

All tools in good condition and made by a reputable manufacturer can be sharpened. If it cannot be sharpened for any reason, we will not charge for the service.

How We Hone

All honing services are performed by hand on traditional Japanese waterstones. This process results in the finest possible edge with the least amount of wear and tear on your blades, meaning your tools are safer to use, more functional, and longer-lasting than if they were sharpened with mechanized sharpeners.

We do our best to research and match the honing practices of the original manufacturer. Please be familiar with your manufacturer's warranty and repairs policy before honing with us.

House Calls

We know barbers and stylists carry full schedules. If you are a barber or stylist in the Portland Area who would like to avoid the hassle associated with mailing or dropping off your tools for sharpening, we’ll come to you! To schedule a House Call at your barber shop or salon, call us or email us with your location and availability. We are usually available Wed-Fri afternoons for House Calls. There is no minimum to schedule a House Call and no added fee. We look forward to helping you soon!